Mission & vision

Our pumped-storage power plant

Our Vianden pumped-storage power plant is one of the largest in Europe. Located in the Our valley, it has a total capacity of 1,300 MW and is an important part of the

European interconnected power grid. In addition to the region’s optimal geographical conditions, its technical components form the basis for reliable and efficient operation.

Our pumped-storage power plant

Lower reservoir

The Our river serves as our natural lower reservoir over a length of 7.7 kilometers and has a usable volume of 7.4 million m³ of water. Depending on the operating mode, the water level can vary between 219 and 228 m above sea level.

Dam

Our dam, named after the former bark mill once located here, impounds the lower reservoir above Vianden. It is 30 meters high and 130 meters long. It also houses turbines for internal power needs.

Upper reservoir

Our upper reservoir is an artificial lake with a circumference of 5 kilometers. Like the lower reservoir, it has a usable volume of 7.4 million m³ of water, with the water level varying between 494 and 511 m above sea level.

Intake

The four intakes in the upper reservoir are connected to our machines via pressure shafts. Intake 1 supplies machines 1 to 4, intake 2 machines 5 to 9, intake 3 is connected to machine 10, and intake 4 to machine 11.

Cavern with machines 1 to 9

The underground cavern is 330 meters long, 17 meters wide, and 30 meters high. Our machines 1 to 9 are ternary units, each 23 meters long and rated at 100 MW.

Shaft power plant with machine 10

Machine 10 is housed in a vertical shaft with a depth of 50 meters and a diameter of 22 meters. With a capacity of 200 MW, it is one of the most powerful pump turbines in the world.

Cavern with machine 11

Machine 11 is the result of the most recent expansion of our pumped-storage plant. A new cavern was excavated for this 200 MW pump turbine.

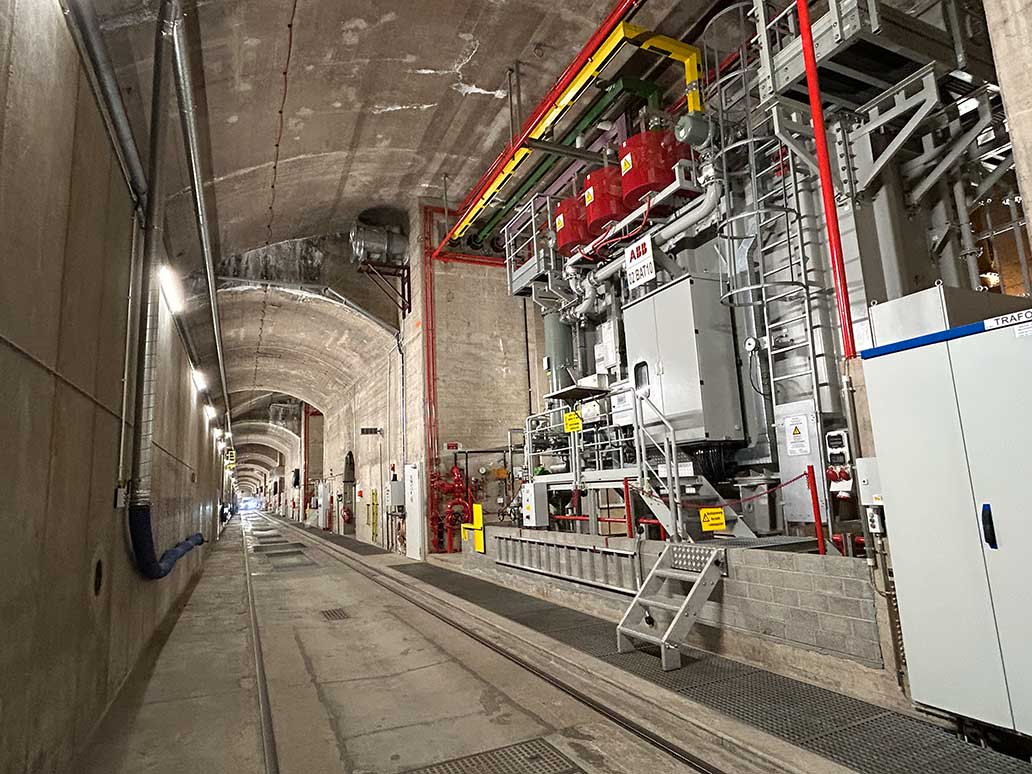

Transformer gallery

Each motor-generator is connected to a transformer, with the transformers for machines 1 to 9 housed in a separate gallery. They convert the voltage from 13,800 V to 220,000 V.

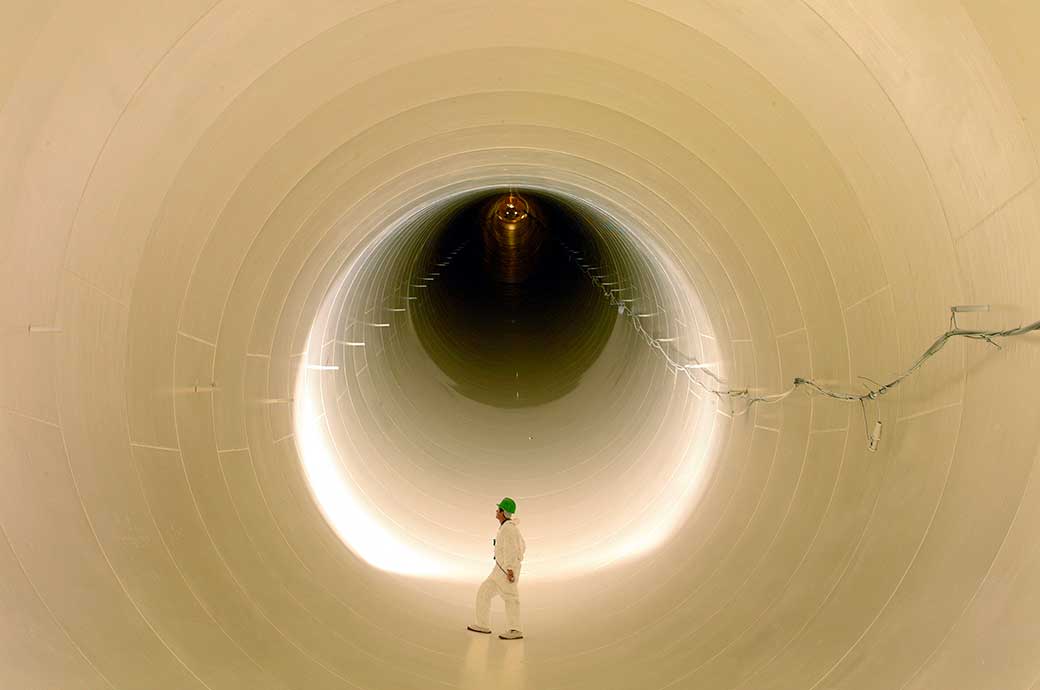

Pressure shafts

Four steel-armored pressure shafts connect the machines to the inlets in the upper reservoir. They must overcome a height difference of 280 meters and have an internal diameter of up to 6.5 meters.

Tailrace tunnels

The tailrace tunnels connect the machines to the outlet structures in the lower reservoir. At the junction with the outlet structure, the tunnels have a diameter of up to 10 meters.

Access tunnels

The access tunnels connect the caverns to the outside world. They provide access for our personnel and allow large transporters to deliver machine components.

Outdoor switchyard

The outdoor switchyard is connected to the machines’ transformers. Its overhead lines lead to the Amprion high-voltage substations, which are part of the European interconnected grid.

Control room

Monitoring and control of the entire power plant, as well as setting the required operating mode of the machines, is carried out by our control room, which is staffed around the clock.